Alloy Designation

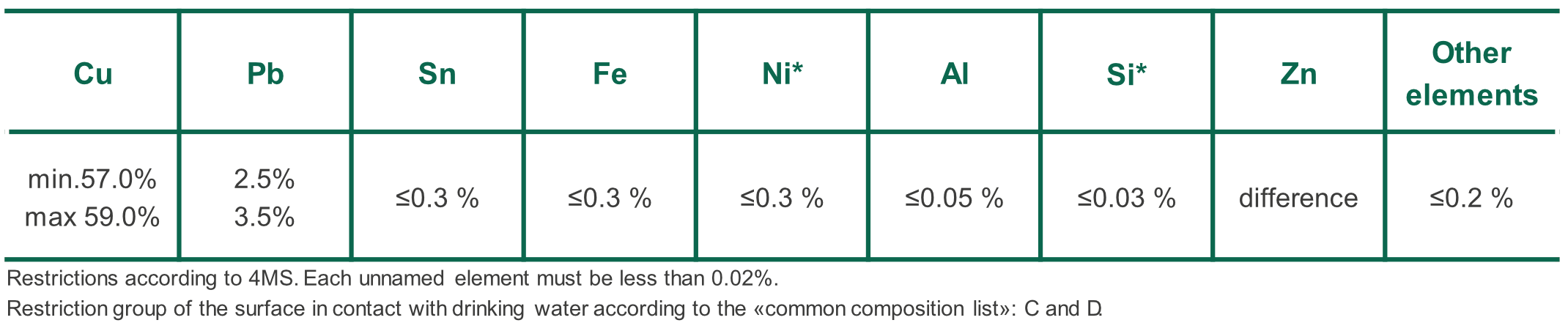

Chemical Composition

UNI EN 12164 ED.2016

Heat treatments

Stress Relieving

It specifically allows redistribution of tension induced by machining or cold plastic deformation, reducing the risk of stress corrosion cracking.

TREATMENT: heating of parts at 200°C to 250°C for 2 hours and cooling within the furnace. Validation of stress relief treatment can be performed with the ISO 6957 test.

Annealing

Recrystallization of the alloy reduces hardness and increases ductility. The treatment temperature ranges from 450°C to 550°C for a period of time relative to the intended result. The high temperature can cause variations in the surface appearance and tolerances of the finished part.

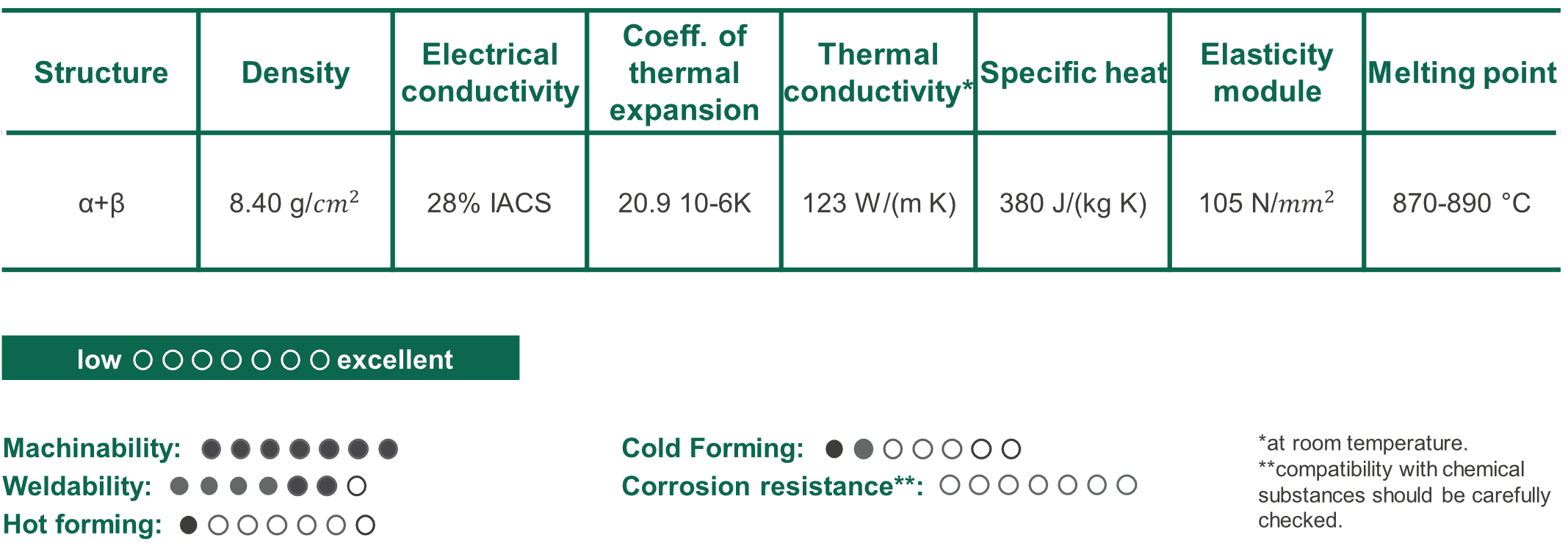

Technological Properties

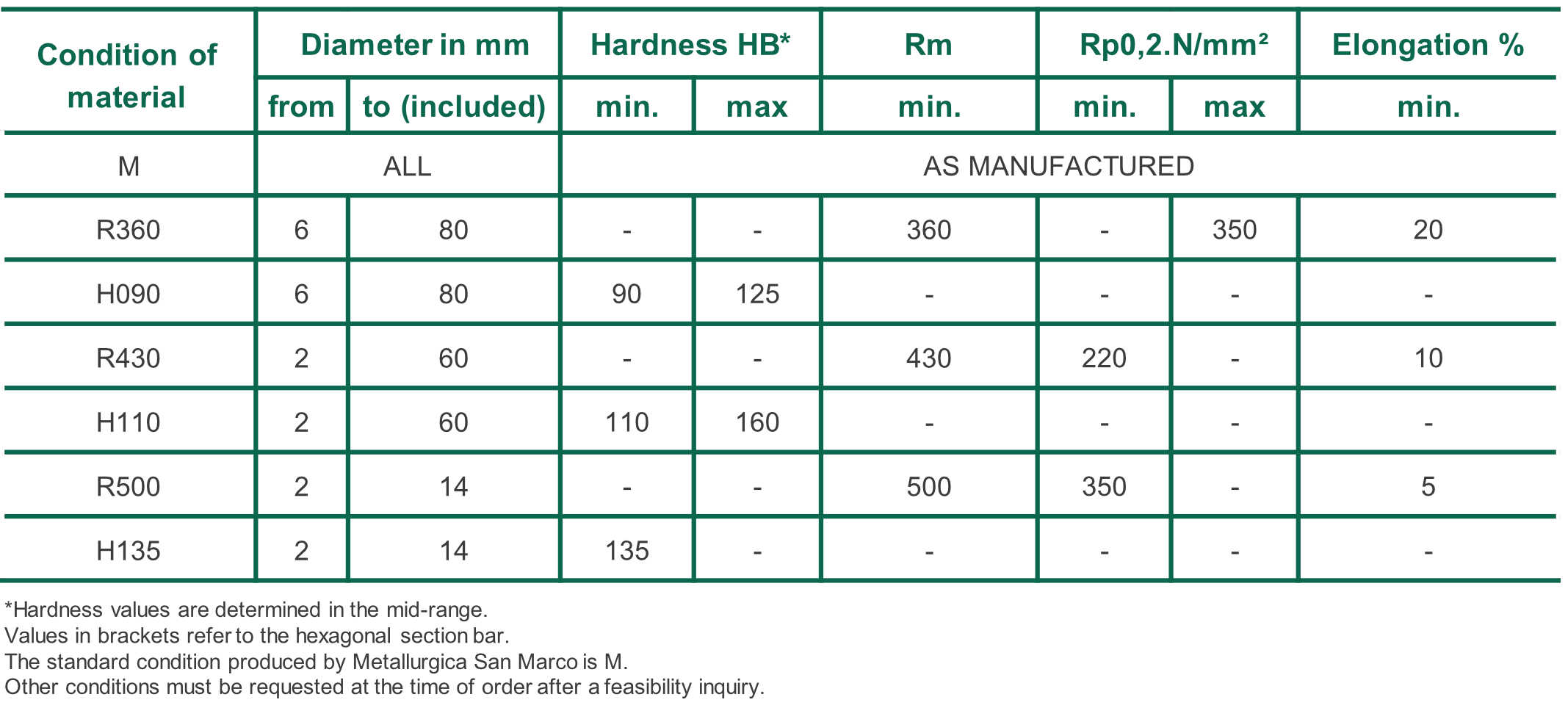

Mechanical Properties

UNI EN 12164 ED.2016

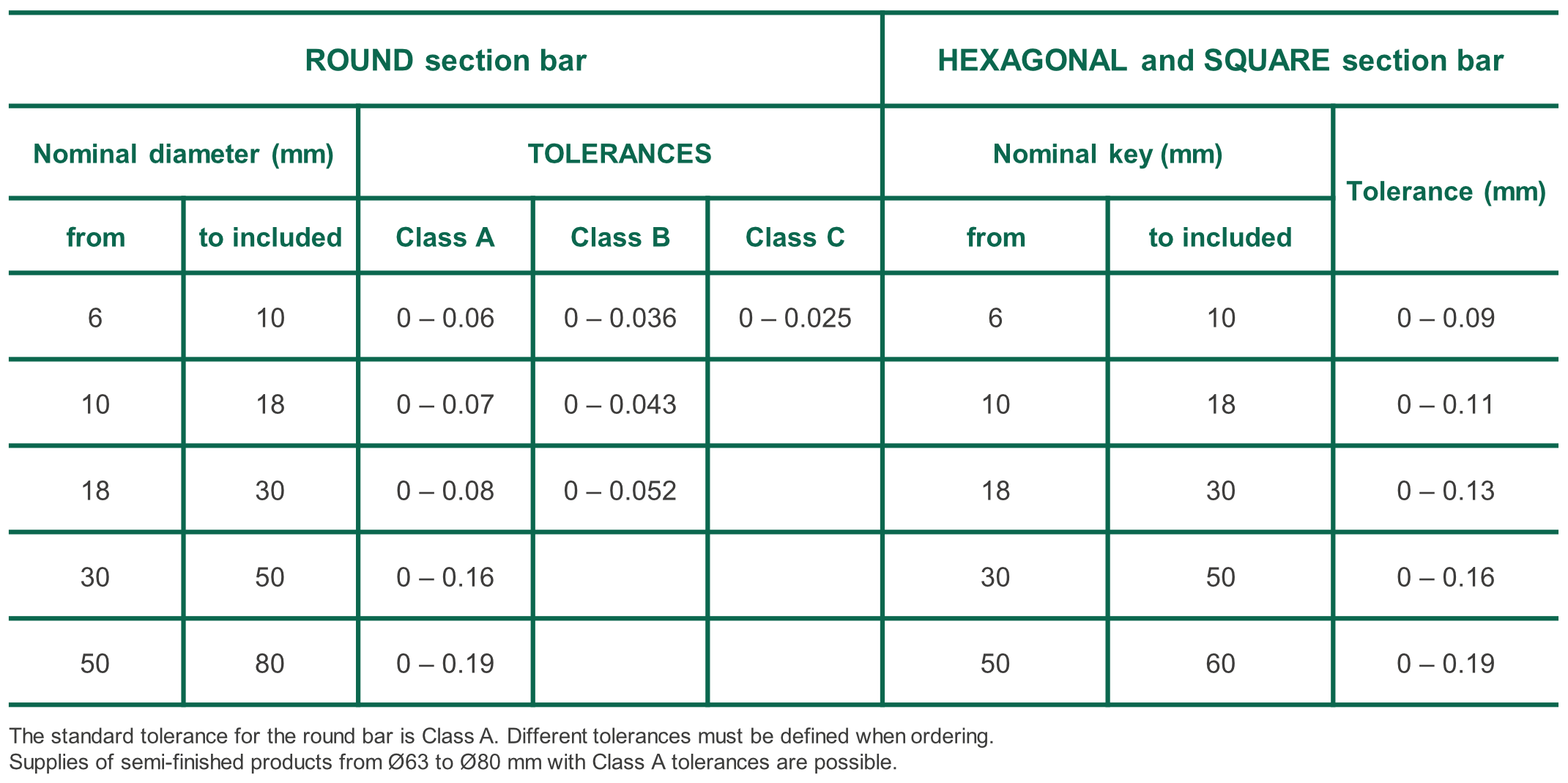

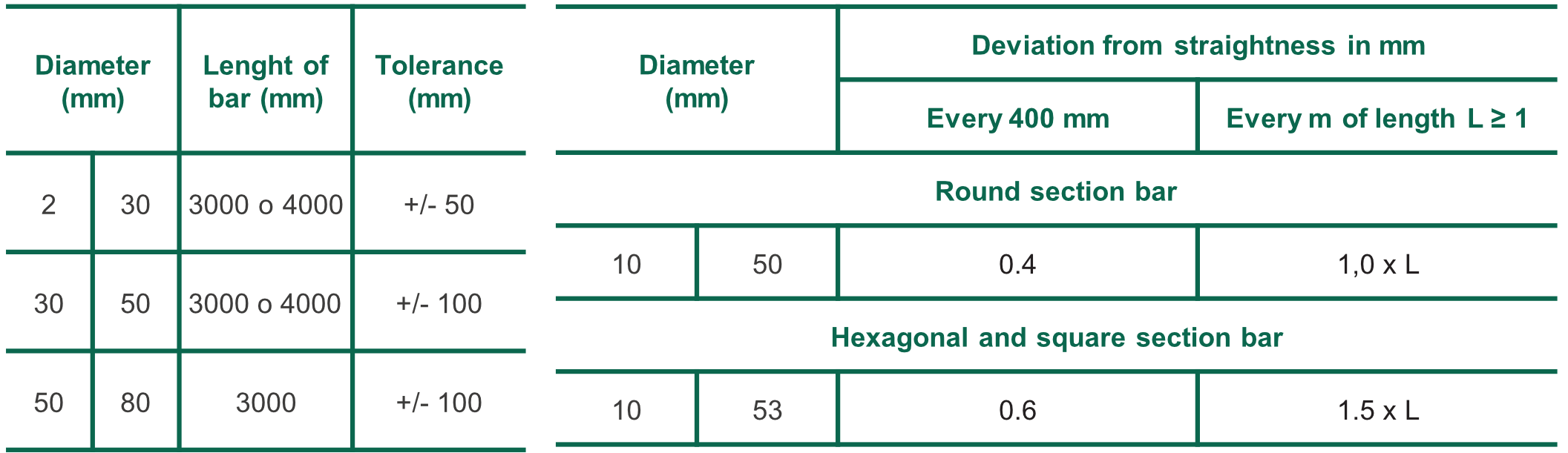

Dimensions, Tolerances, and Straightness

UNI EN 12164 ED.2016

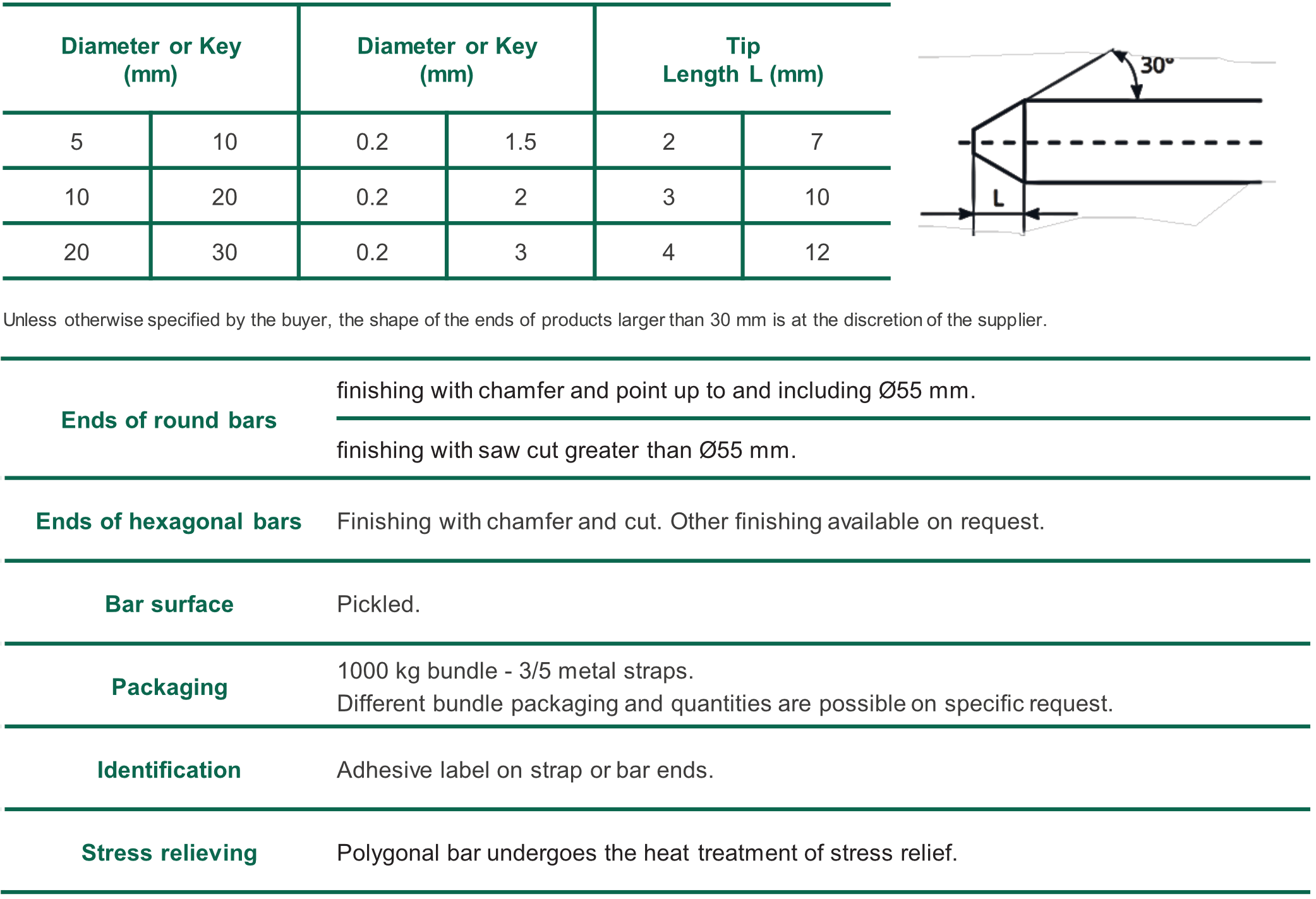

Finishing and Packaging

Technical Notes

This alloy arose from the need to push machining to the extreme. It has excellent chip removal properties whose dimensions are reduced due to its balanced chemical composition. It finds application in faucets, general components.